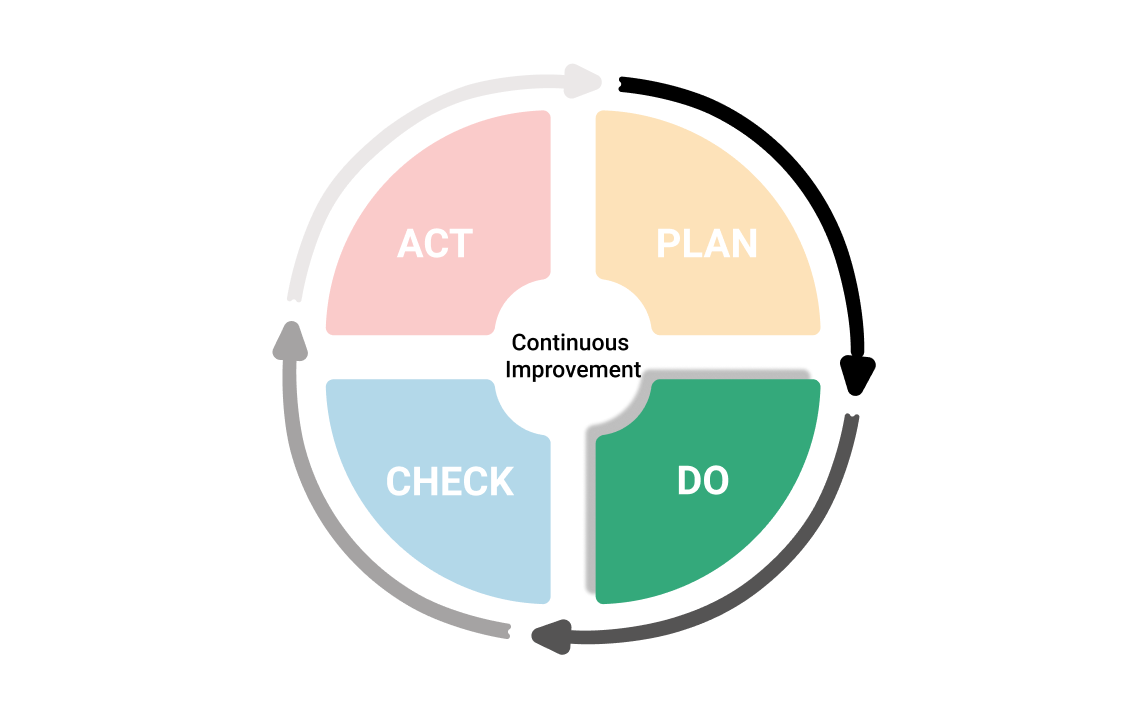

Plan Do Check Act Cycle

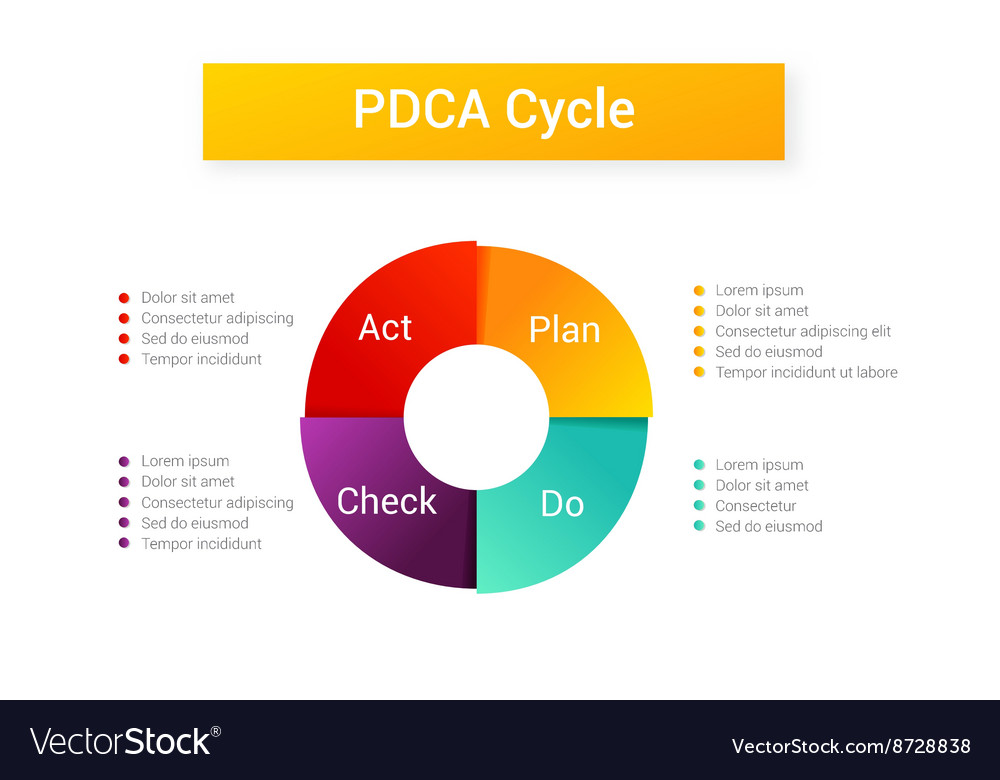

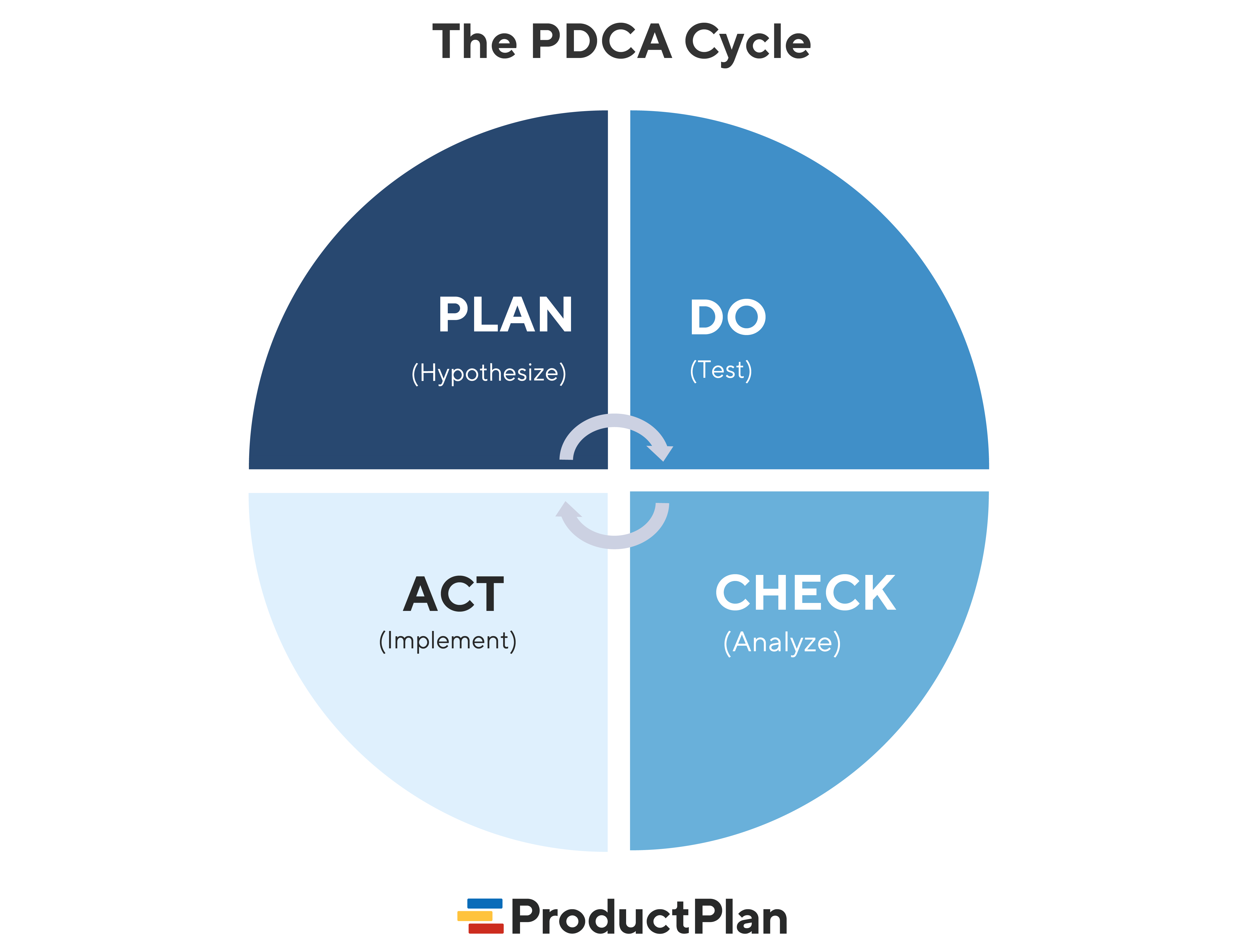

The PDSA Cycle Plan-Do-Study-Act is a systematic process for gaining valuable learning and knowledge for the continual improvement of a product process or service.

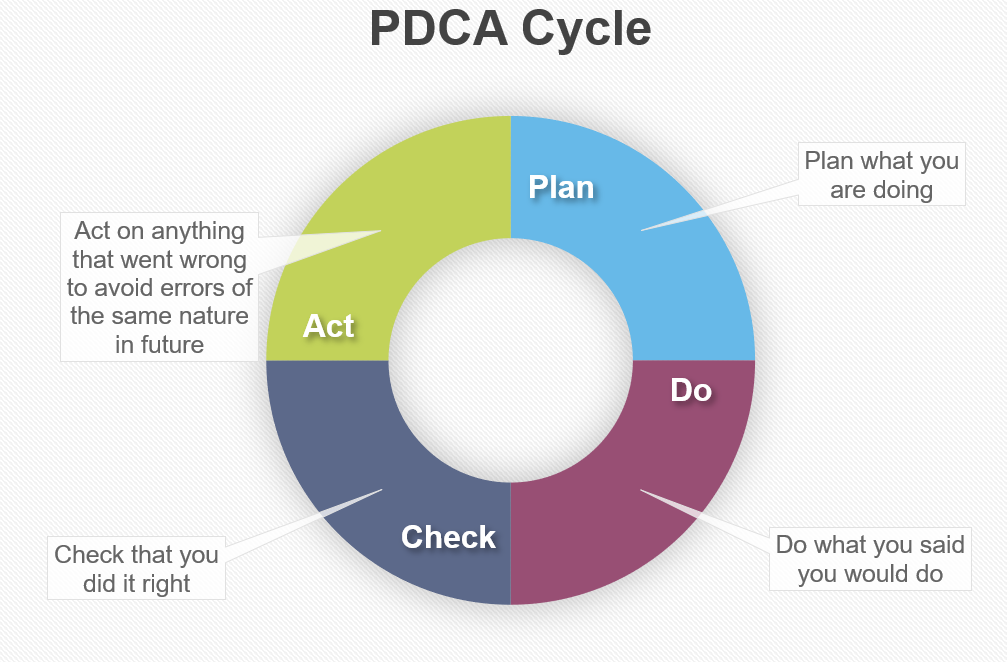

Plan do check act cycle. The PDCA Cycle is also known as the Deming Cycle. The Plan Do Check Act PDCA cycle as much as a lot think is not related to the CAPA process only. The Plan-Do-Check-Act PDCA cycle also known as the Deming wheel or the Deming cycle is an iterative method for continual improvement of processes products or services and is a key element of lean management.

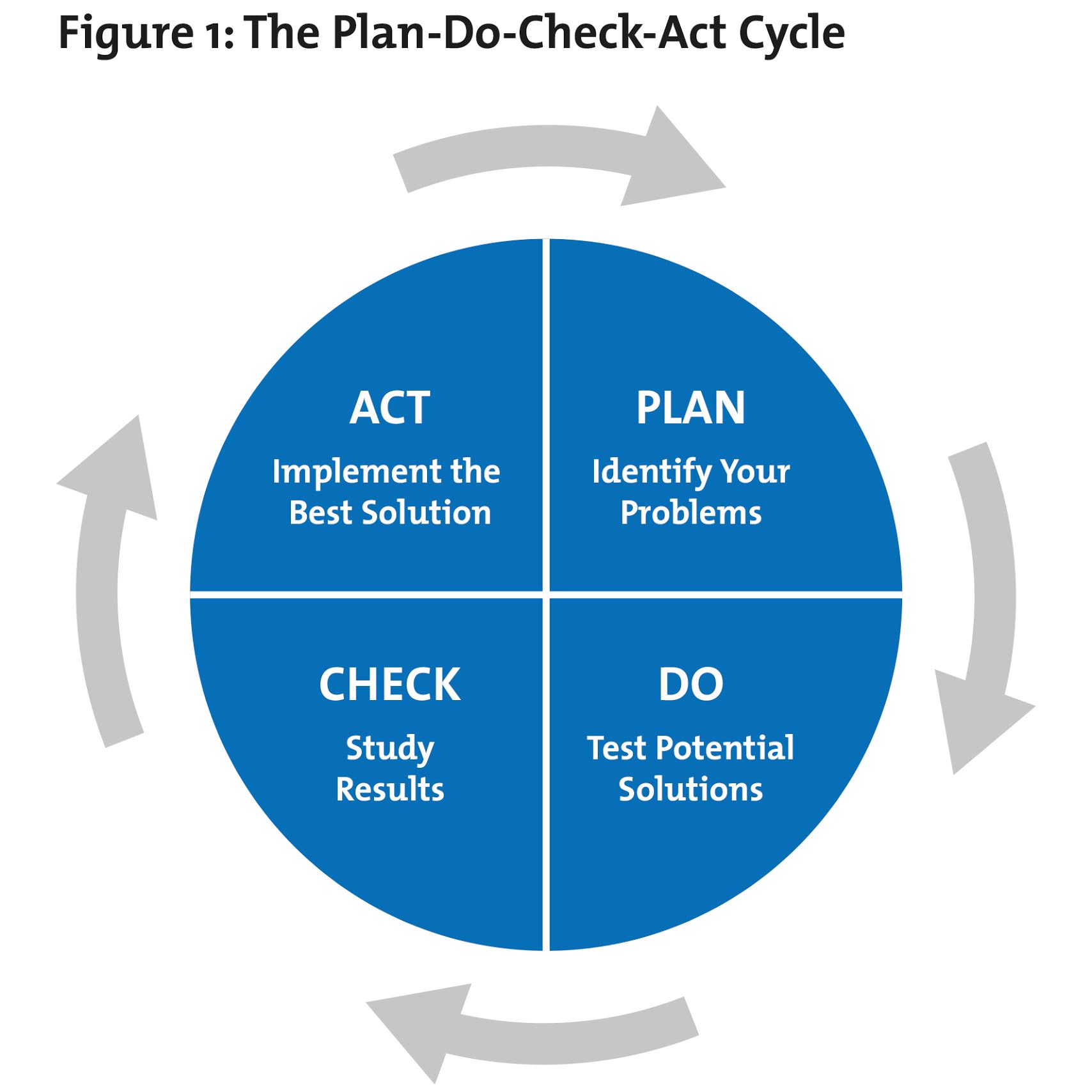

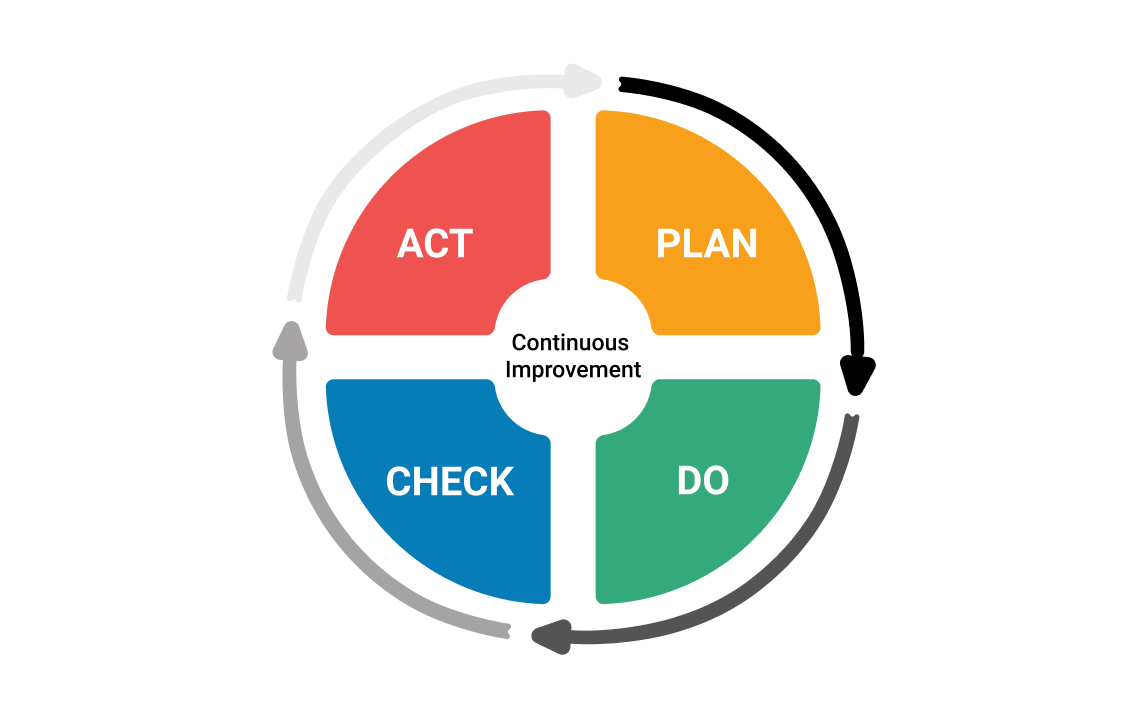

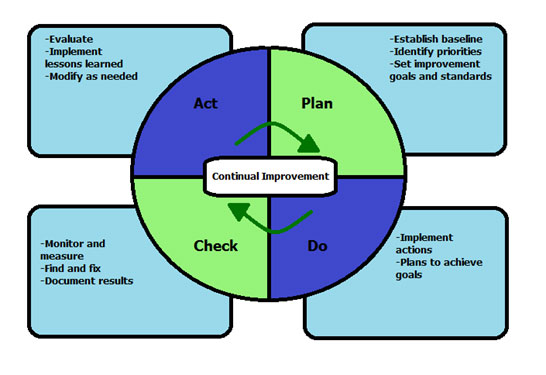

This cycle has no end and it can be repeated over again for continuous improvement. Plan-do-check-act PDCA is a four step cycle that allows you to implement change solve problems and continuously improve processes. The Plan-do-check-act cycle Figure 1 is a four-step model for carrying out change.

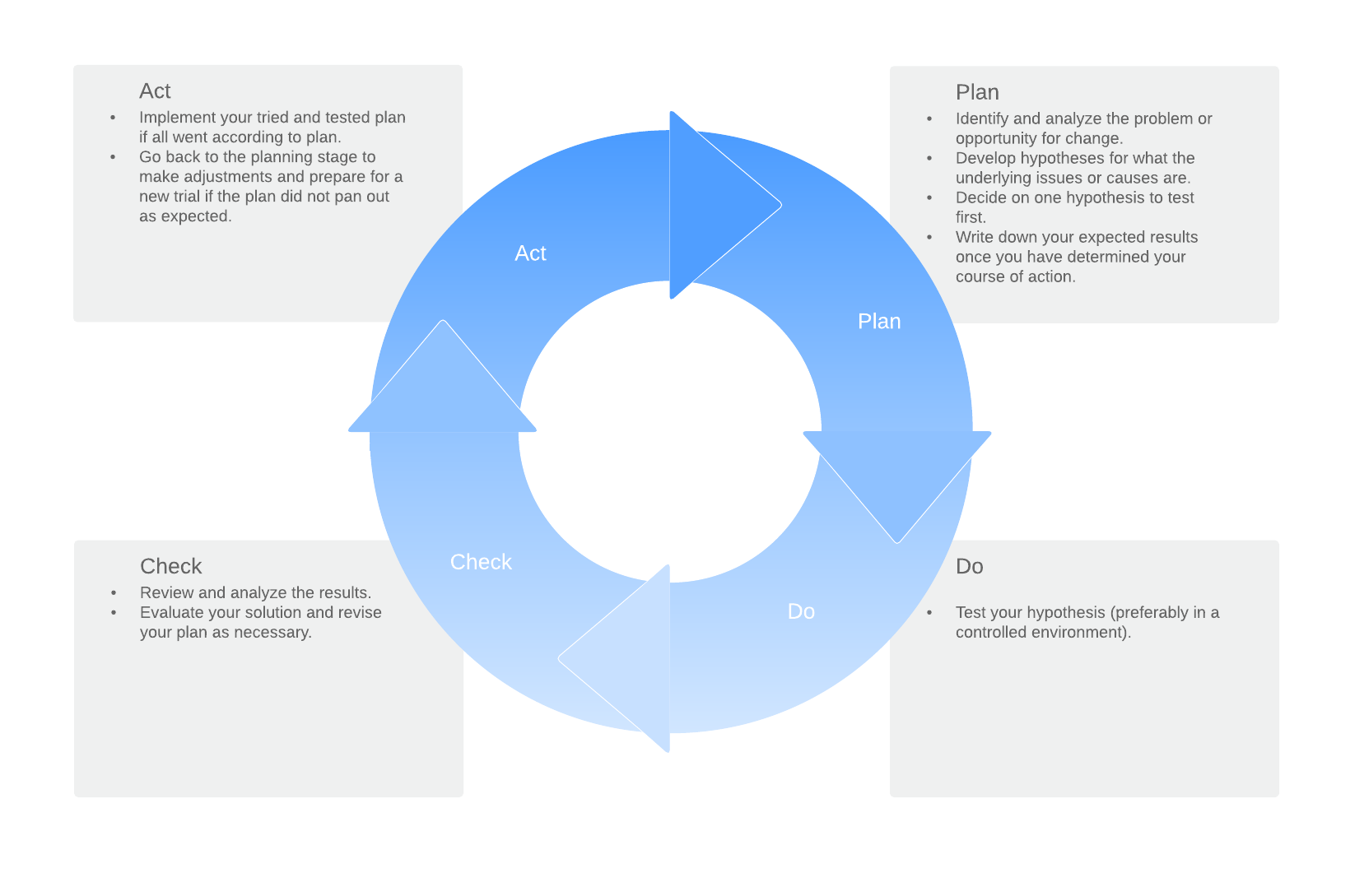

It is also known as the Deming circle cycle wheel the Shewhart cycle the control circle cycle or plandostudyact PDSA. Plan-Do-Check-Act cycle is a useful tool that can help your team solve problems much more efficiently. PDCA plandocheckact or plandocheckadjust is an iterative design and management method used in business for the control and continuous improvement of processes and products.

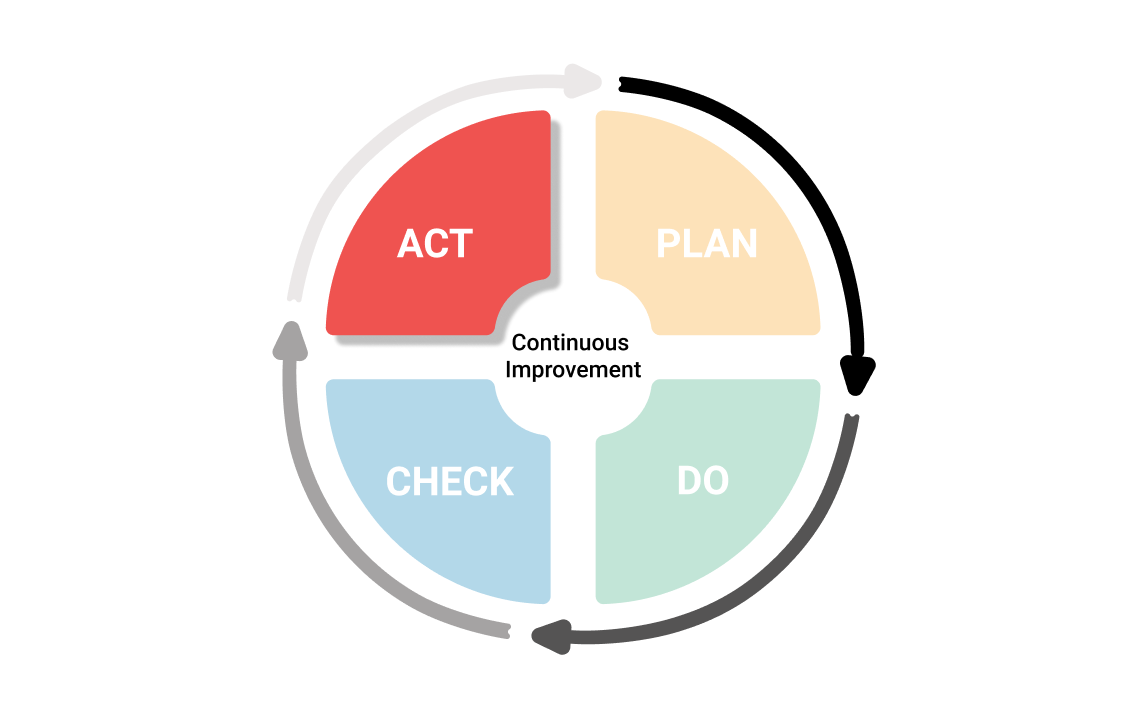

Therefore this cycle is called a loop. PDCA is a successive cycle which starts off small to test potential effects on processes but then gradually leads to larger and more targeted change. Its cyclical nature allows it to be utilized in a continuous manner for ongoing improvement.

Plan-Do-Check-Act PDCA solution extends the ConceptDraw PRO software with collection of samples and predesigned vector objects for easy visualization four stages of PDCA cycle PDSA cycle or Deming cycle for illustration effective application of this method to the practical business tasks for depiction the implementation of changes and solution the problems in. Also known as the Deming Wheel or Deming Cycle this integrated learning - improvement model was first introduced to Dr. PDCA stands for Plan Do Check Act.

Just as a circle has no end the PDCA cycle should be repeated again and again for continuous improvement. First proposed by Walter Shewhart and later developed by William Deming the PDCA cycle became a widespread framework for constant. It lets your team test possible solutions on a small scale and in a controlled environment.

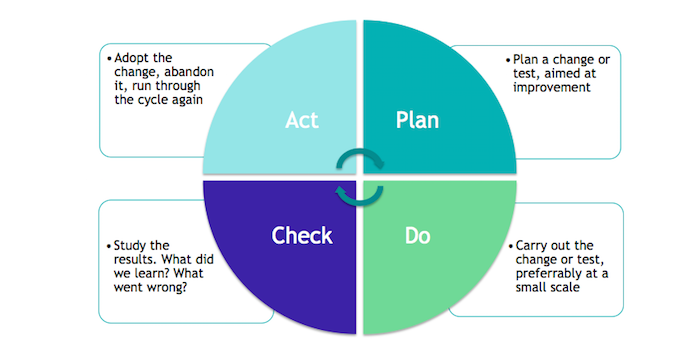

The cycle begins with the planning phase Plan then it goes to the production or doing phase Do after which the results are evaluated Check in order to provide better satisfactory results Act. This site teaches you the skills you need for a happy and. It prevents the work process from recurring mistakes.

The PDCA cycle is considered a project planning tool. PDCA has some significant advantages. Plan-do-check-act is a four-step model that carries out the change in a process product or service.

The Plan Do Check Act PDCA Cycle is a four-step method used in the process of continuous improvement. The principle of the PDCA cycle can be maintained throughput all all of our daily business aspects. PDCA stands for Plan-Do-Check-Act a four-stage problem-solving model that enables organizations to continually improve processes products or services.

Moreover this model is considered as a project planning tool. In the 1920s Walter Shewhart created the Plan Do See concept which was known as the Shewhart Cycle. It is also called Demings cycle or Shewhart cycle.

Go through the Do and Check stages as many times as necessary before the full polished solution is implemented in the Act phase of the cycle. It is an essential part of the lean manufacturing philosophy and a key prerequisite for continuous improvement of people and processes. Plan-Do-Check-Act Cycle PDCA Cycle PDCA cycle is one of the simplest and the easiest management approaches for process control and continuous improvement.

It stimulates continuous improvement of people and processes. PDCA plandocheckact is an iterative four-step quality improvement and management agile process typically used for the better of the business strategy. We use it both formally and informally.

The PDCA Cycle which stands for Plan-Do-Check-Act is a problem-solving iterative technique that uses four steps to improve business processes. Actually the PDCA cycle is true to all elements and requirements of a quality management system. Deming by his mentor Walter Shewhart of the famous Bell Laboratories in.

The Plan-Do-Check-Act cycle was first used in Japan and resulted to the implementation of Kaizen good change in the country. Explained briefly the Plan-Do-Check-Act cycle is a model for carrying out change.