Exposure Control Plan Osha

Each employer will need to adjust or adapt the model for their specific use.

Exposure control plan osha. Be sure your facilitys Exposure Control Plan meets OSHAs criteria. This instruction provides for uniform policy for protection of OSHA personnel who as part of their job face reasonably anticipated exposure to bloodborne. The information contained in this publication is not considered a substitute for the OSH.

The exposure control plan is a vital document that allows our business to comply with the required standard providing a high level of protection to our employees. OSHAs mission to protect workers may be a costly and time-consuming endeavor for your business but in the end it will help you avoid fines unnecessary workplace compensation issues loss of staff due to temporary injury and even staff turnover. Click on the link here for a Model Exposure Control Plan.

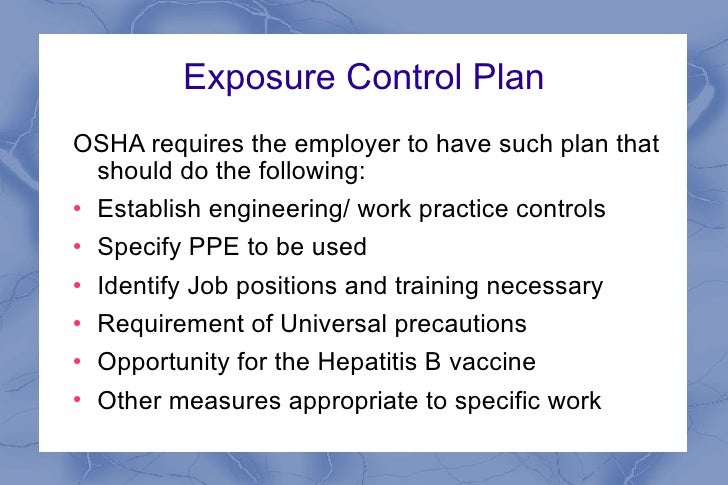

This sample program can be found at the end of this chapter. OSHA requires employers to perform an exposure determination concerning which employees may incur occupational exposure to blood or other potentially infectious materials. This Exposure Control Plan applies to all BU personnel with occupational exposure to human materials including body fluids or tissues or other potentially infectious materials as defined by OSHA.

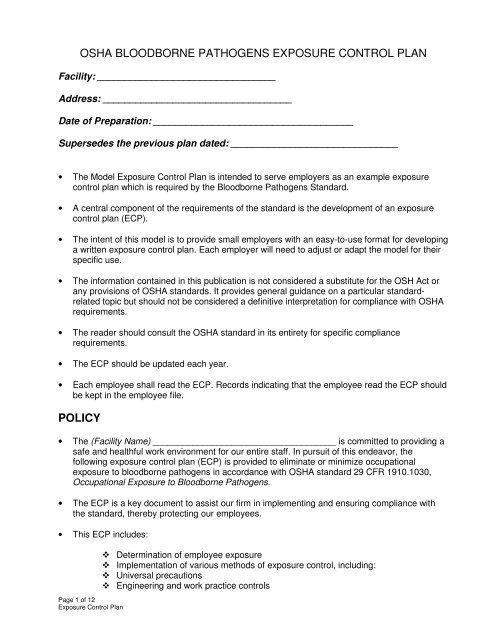

The intent of this model is to provide small employers with an easy-to-use format for developing a written exposure control plan. It must be written specifically for each facility. It was distributed under the provisions of the Library.

Requirements of the standard is the development of an exposure control plan ECP. This plan also outlines the requirements West Central. Exposure Control Plan for Federal OSHA Personnel with Occupational Exposure to Bloodborne Pathogens A.

The details included in an exposure control plan should be specific to each shop. Per the OSHA Bloodborne Pathogens Standard an Exposure Control Plan must meet certain criteria. Exposure Control Plan 2010 Stericycle Inc.

If exposures to blood or other body fluids are reasonably anticipated you are required by the Occupational Safety and Health Administration OSHA Bloodborne Pathogens Standard to develop an Exposure Control Plan. OSHA Instruction CPL 2-260 March 7 1994 Office of Occupational Medicine SUBJECT. In accordance with the OSHA Bloodborne Pathogens standard 29 CFR 19101030 the following exposure control plan has been developed.

Rev110 The ECP is a key element in the protection of our employees and at the same time it also assists our facility in ensuring compliance with the OSHA Standard. The document was prepared for publication by the staff of CDE Press California Department of Education. A full description of employee exposure.

It pays to be diligent in writing and maintaining your Exposure Control Plan. Determination of employee exposure Implementation of various methods of exposure control including. The Exposure Control Plan for Bloodborne Pathogens was developed by the Education Unit CalOSHA Consultation Service California Department of Industrial Relations.

The following Bloodborne Pathogen Exposure Control Program is provided to eliminate or minimize occupational exposure to bloodborne pathogens in accordance with OSHA standard 29 CFR 19101030 Occupational Exposure to Bloodborne Pathogens. Dictated by OSHA as a part of the Occupational Exposure to Bloodborne Pathogens. Established cultured human cell lines are also included as potential blood borne pathogens whether characterized to be free of contamination or not.

Written exposure control plans provide a systematic approach for. If a contractor does not currently have a written plan this outline can be used to develop one. Written Exposure Control Plan Hilti Inc.

The purpose of the ECP is to establish procedures to eliminate or minimize employee exposure to bloodborne pathogens. According to the OSHA Bloodborne Pathogens Standard an Exposure. An employer exposure control plan ECP is a requirement of 29 CFR 19101030 c of the Bloodborne Pathogens Standard established by the Occupational Safety and Health Administration OSHA.

It must be reviewed and updated at least yearly to reflect changes such as new worker positions or technology used to reduce exposures to blood or body fluids. V An employer who is required to establish an Exposure Control Plan shall solicit input from non-managerial employees responsible for direct patient care who are potentially exposed to injuries from contaminated sharps in the identification evaluation and selection of effective engineering and work practice controls and shall document the solicitation in the Exposure.