Control Plan Six Sigma

Complacency and anxiety can set in for the sake of bringing closure receiving credit for executing a project.

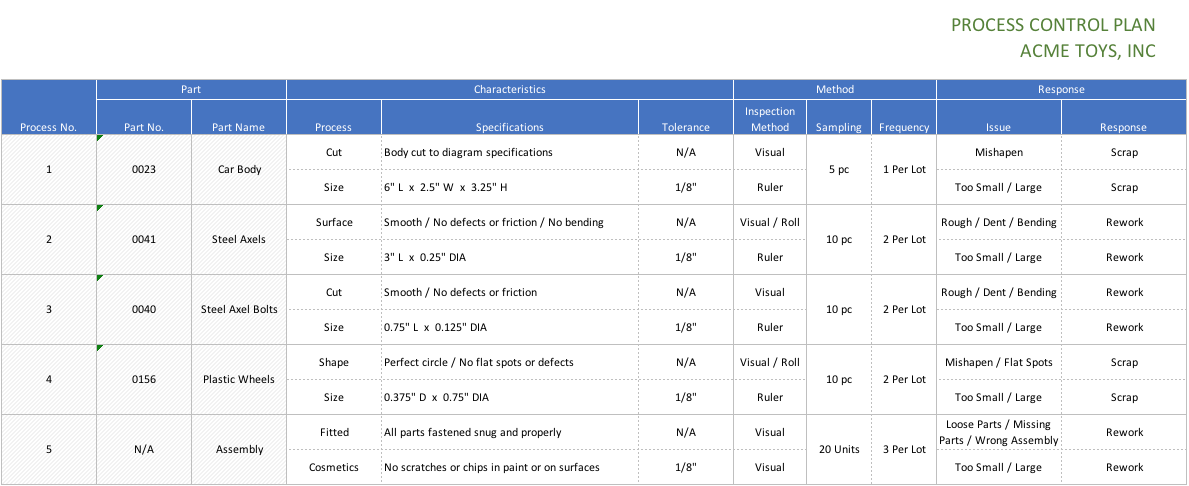

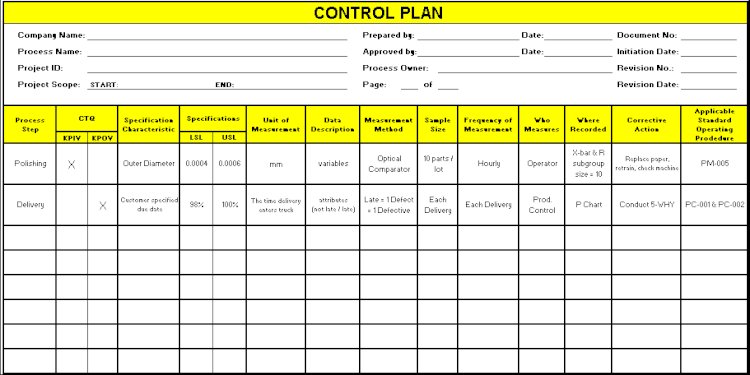

Control plan six sigma. A Six Sigma Control Plan offers a single point of reference relevant to the understanding of process specifications characteristics as well as standard operation procedures or SOPs. There can not be enough emphasis placed on the importance of devoting the same high level of energy and commitment throughout this phase. It lays down the grounds for the assignment of responsibilities for all activities within the processes.

According to the American Society For Quality ASQ the purpose of the control plan is to ensure that performance improvements made by the project team are sustained over time. For evaluating the performance of the process some measurement criteria would have to be decided. Six Sigma is a systematic problem solving approach centered around defects elimination and variation reduction leading to process improvement.

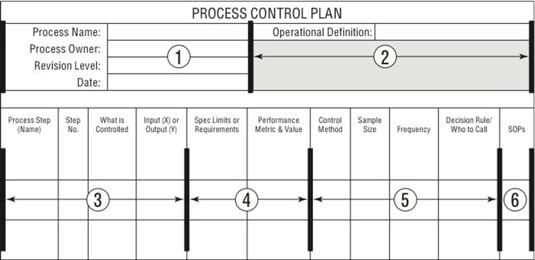

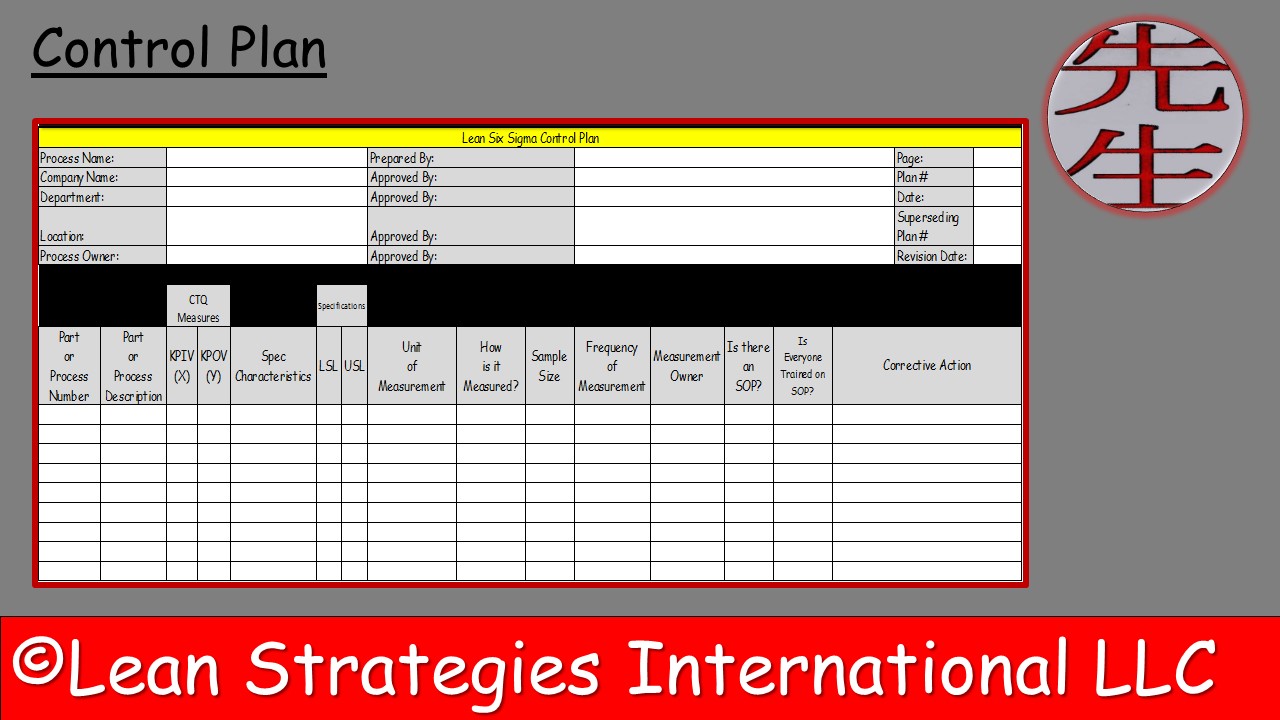

This ensures that the process doesnt revert to the way it previously operated. What is The Purpose Of A Six Sigma Control Plan. A Control Plan is often considered one of the mandatory activities and documents that need to be done in the Control Phase of a Six Sigma DMAIC project cycle.

Processes that operate with six sigma quality over the short term are assumed to produce long-term defect levels below 34 defects per million opportunities. Overall a well-designed control plan is instrumental in executing all processes smoothly and. Six Sigma Template Control Plan is one of the best methods for documenting the functional elements of quality control that are to be implemented in order to assure that quality standard is met for a particular product or service.

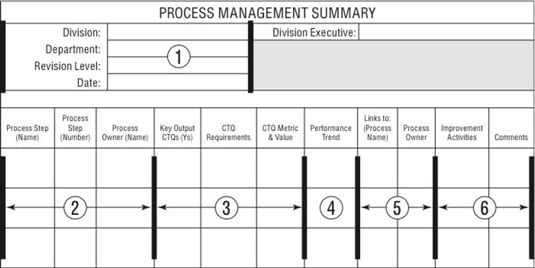

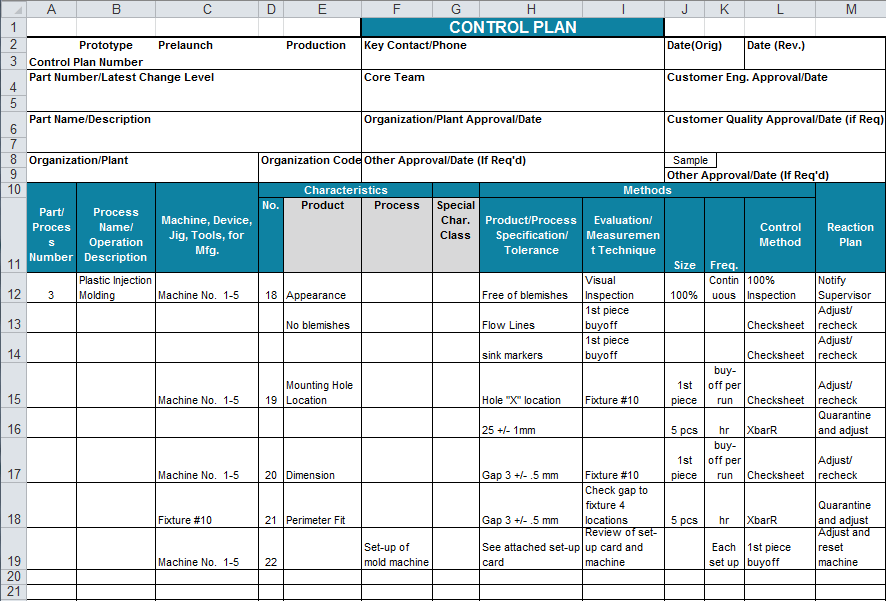

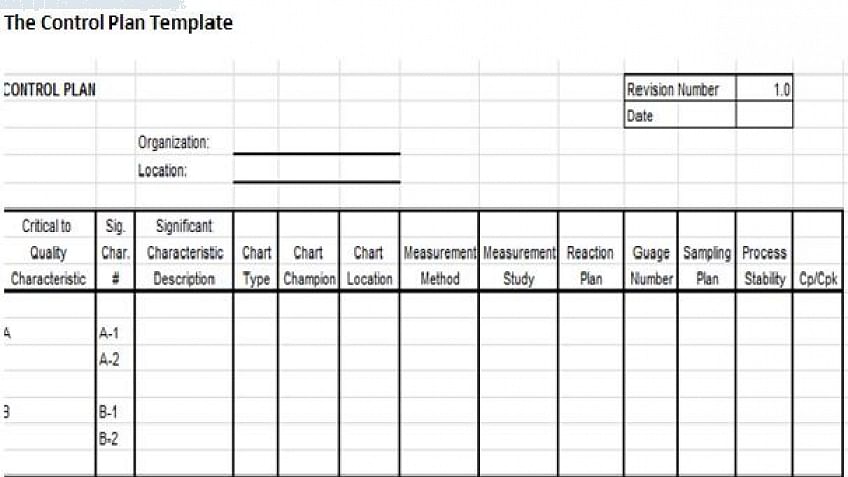

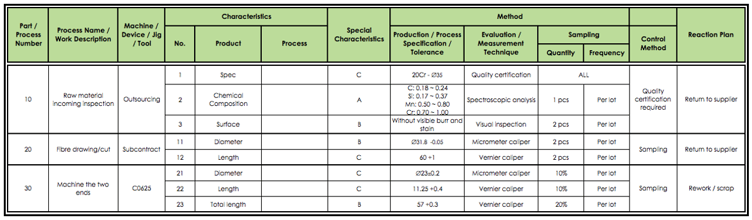

Control plan construction is often led by the black belt incharge of the six sigma project. A control plan for a Six Sigma project can be displayed on a spreadsheet or in a simple table. The team is usually cross functional with individuals from different areas including the process owner.

The four techniques used for process control plans are. Also see DMAIC Overview. Control Plan Control Chart and Monitoring Response Plan.

Six Sigma DMAIC Process - Control Phase - Control and Implementation Plans. Control Phase of a DMAIC Six Sigma project. Document the Improved Process.

Six Sigma Control Plan Template. One of the principal tools in Six Sigma is the use of the DMAIC methodology. Control Plans are extensively utilized by Six Sigma professionals and are an integral part of the Six Sigma set of methodologies.

Control plans are typically made up of the following six sections that contain critical details about the process. The Six Sigma Project Manager hands the project off to the Champion who monitors the performance over the long term. A Control Plan is developed by the Six Sigma team.

The contents of a Control Plan. The term 6 Sigma refers to the ability of manufacturing processes to produce a very high proportion of output within specification. One of the best ways to increase the power and bang for the buck of any Lean Six Sigma effort is to apply the discoveries from the project into other areas within the organization.

With any other activity in Six Sigma there are certain protocols rules and regulations one needs to follow while updating the Control Plan. The intent of the control plan is to formalize and document the system of control that will be utilized. Even if its not feasible to transfer the entire project there may be parts of it that could be.

The team will ensure that the control plan contains the critical variables the Xs and the Ys of the product or process. A Control Plan is a method for documenting the functional elements of quality control that are to be implemented in order to assure that quality standards are met for a particular product or service. The aim of this control plan is to formalize documentation of the system of control that will be utilized.